Washing of ready-made garments

Active water-based dyeing is a textile dyeing technology that uses water as the medium and achieves coloring through the covalent binding of active dyes with fibers. It is characterized by both environmental friendliness and dyeing durability.

ZEE team

We specialize in the field of active dyeing for ready-made garments and serve as a service provider for clothing brands, manufacturing enterprises and customers by offering professional dyeing solutions. With a deep understanding of the characteristics of active dyes and the dyeing process for garments, we provide precise, stable and environmentally friendly dyeing processing services for various natural fibers such as cotton, linen, silk and wool, as well as regenerated cellulose fibers.

Our core strength lies in the ability to customize exclusive dyeing plans for different fabric components and garment structures (such as patchwork, accessories), from the initial detection of fabric components, dye ratio adjustment, to the precise control of temperature, pH value, and time during the dyeing process, to the fixation, color removal and softening treatment after dyeing, all of which are strictly followed according to industry standards to ensure uniform and consistent colors of the garments, high matching with color cards, and at the same time guarantee excellent wash fastness and rubbing fastness of the dyed garments, avoiding fading and color transfer problems. Whether it is to meet the small-batch multi-color design requirements of brands, to re-color and refresh inventory garments, or to repair fading and color differences after garment washing and wearing, we can meet diverse dyeing and color restoration needs with professional technology.

Garment washing offers four core benefits for finished apparel

Softness

Processes like enzyme washing create a plush, comfortable handfeel.

Color Fastness

Special fixing steps reduce fading and color bleeding after wear/laundering.

Shrinkage Control

Pre-washing minimizes dimensional changes in consumer use.

Aesthetic Enhancement

Techniques like stone washing add vintage, distressed looks for unique design value."

Denim washed with water

The denim washing process involves treating denim garments through physical, chemical or biological methods to achieve the core processing steps of achieving an aged style, soft texture, control of shrinkage and beautification of appearance. The ultimate goal is to make the hard and raw denim fabric produced initially present a natural and retro wearing texture and give it a unique visual effect.

All water washing processes are centered around the following four core goals to meet consumers' requirements for the wearing experience and aesthetic preferences of denim clothing: Improving the feel: By washing, the starch and some cotton fibers on the surface of denim fabric are removed, making the originally stiff fabric become soft and comfortable, and facilitating wearing. Controlling shrinkage: Denim fabric (especially cotton-based) has a natural shrinking characteristic. The water washing process can pre-allow the fabric to complete most of the shrinking, avoiding significant size changes after consumers wash it. Achieving an aged style: This is the core aesthetic value of denim water washing. Through different processes, it simulates the natural wear and fading effects after long-term wearing, such as cat whiskers, bleaching, and holes. Color fixation and cleaning: Removing the residual floating colors and impurities on the fabric during production, and through color fixation treatment, reducing the fading and color transfer problems during subsequent wearing and washing.

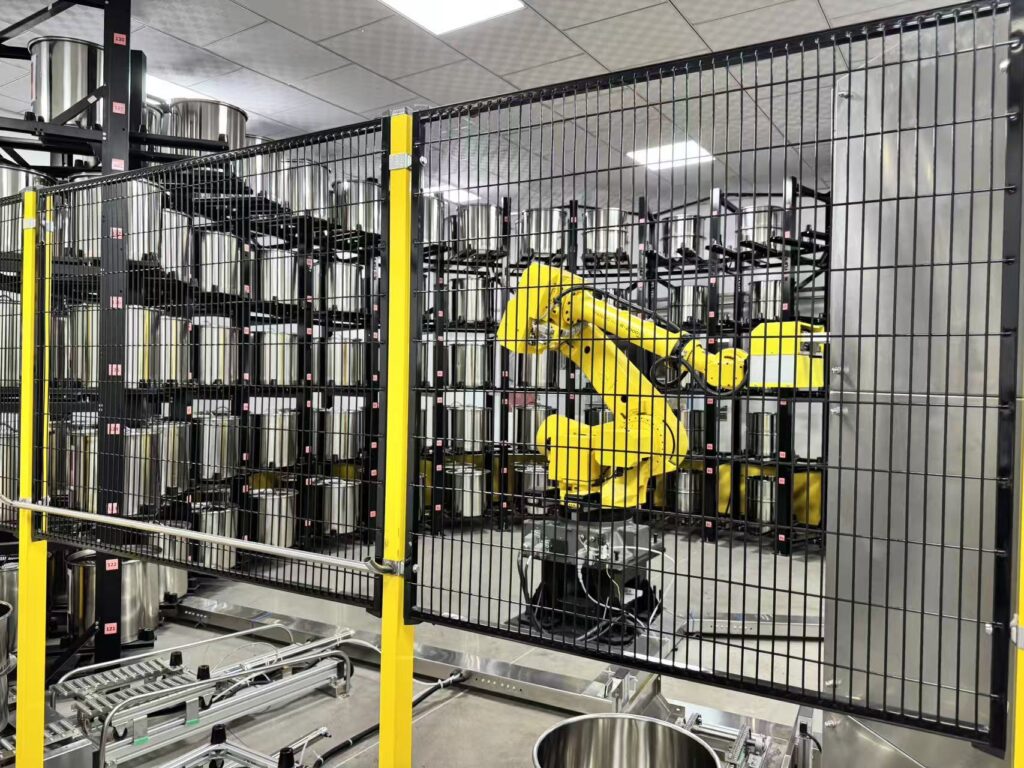

Intelligent color adjustment system

Mix the dyes and additives in a certain proportion to form the working solution, which has the functions of color difference detection and automatic correction.